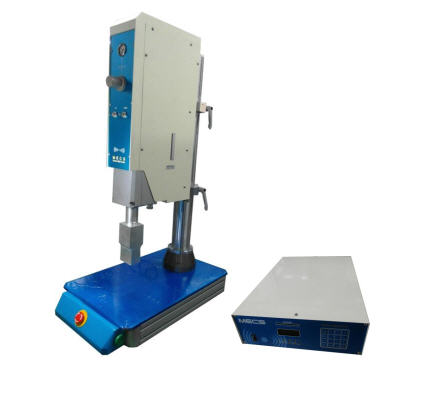

MT-1030AC+

Ultrasonic Plastic Welding (MT-1030AC+)

Hoặc gửi yêu cầu tư vấn:

Chi tiết sản phẩm

- Wide Range Automatic Tuning System

– 30 KHz ± 700 Hz

Maintaining an optimized condition with tracking the change of frequency caused by wearing tool horn and increasing temperature while tool horn working. - Saving Working Frequency & Displaying Actual Frequency

It is available to keep the optimized condition oscillating with the saved frequency after welding. And displaying the actual frequency makes to check and manage the converter easily. - AVR function built-in

Constant amplitude is maintained regardless the input voltage change of 180 ~ 260 Volt.

(In general model, there is amplitude fluctuation of ± 10%, in case of input power change of ± 2%) - 2 steps constant amplitude function

Keeping constant amplitude with 2 steps amplification function of generator applied FET or IGBT and AVR device regardless loading condition. - The most advanced digital ultrasonic generator

The digital type ultrasonic generator is able to control precisely regardless environment variation or component error. (Applying 3 pieces of EPLD and 5 pieces of CPU) - Digital type soft start and adjustment of 8 steps power raising speed

Supplying the output almost linearly rather than steps prevents the damage on the tool horn and generator, which may happen due to the shock wave while oscillating the ultrasonic initially. It is available to adjust the starting output speed to eight (8) steps depending on the tool horn size and welding product condition.

(Example : for large tool horn at 150ms and low pressure-high output welding at 50ms starting velocity) - Electronic Amplitude Adjustment Function ( 10 – 100 % )

Providing an easy adjustment for amplitude by a switch without changing the main horn and a optimum welding condition according to welding material and product condition. - Precise Overload Protection Device

Protecting completely the damage on generator and main horn through checking current, voltage, phase and frequency. - Low Pressure – High Power Welding Function

Applicable to precise welding with complicated product and material because it is available to reach a maximum power within 0.05 second at low pressure in order to prevent scratch and product damage. - The Most Advanced Digital Control Device

Displaying various welding condition and information, controlling the welding time at 0.01 unit. - Memomry for Welding Conditions

Available to save and read up to 10 memory welding condition, which makes easy for applying to various welding products. - Self-Check for Good or Bad Welding Quality

Welding quality control to check good or bad welding quality by itself according to the setting value range in energy mode or time mode while welding. - Alarm Function

Displaying various messages including machine malfunction, bad welding quality on the LCD screen. - 2 Steps Amplitude Function

Contributing to precise welding operation and improving the welding strength for non-crystalline materials such as ABS and Acryl. - Application for Additional Pneumatic Jig and Transfer Jig

Equipping the control device for external pneumatic equipment (fixing clamp, transfer jig and soundproof door) in the control unit. - Accept Jig plate casting that can adjust horizontal (Option)

There is a casting construction that absorbs vibration. It can adjust control because it is far from horizontal adjusting bolt. The setting value is not changed because of durable of fixed jig. - Table (Option)

For storage the generator or put in the machine on the table. There are wheels under the table. It is easy to move and there is the fixed adjusting horizontal equipment. - Air Pressure Servo Valve (Option)

Need to adjust the minute pressure - Load Cell Pressure Trigger Equipment (Option)

It can be accurately welded by ultrasonic of same pressure.

Thông số kỹ thuật

|

Model No. |

MT-1030AC |

|

|

Frequency |

30 KHz ± 750 KHz |

|

|

Output |

1,000 Watt |

|

|

Input power |

180 ~ 260 Volt. single phase 50/60Hz |

|

|

Stroke |

100mm |

|

|

Pneumatic pressure |

6 bar clean air |

|

|

Pressurization |

Max. 50Kg |

|

|

Generator |

Size |

600(L) x 440(W) x 150(H)mm |

|

Weight |

18 Kg |

|

|

Actuator |

Size |

500(L) x 280(W) x 750(H)mm |

|

Weight |

35 Kg |

|